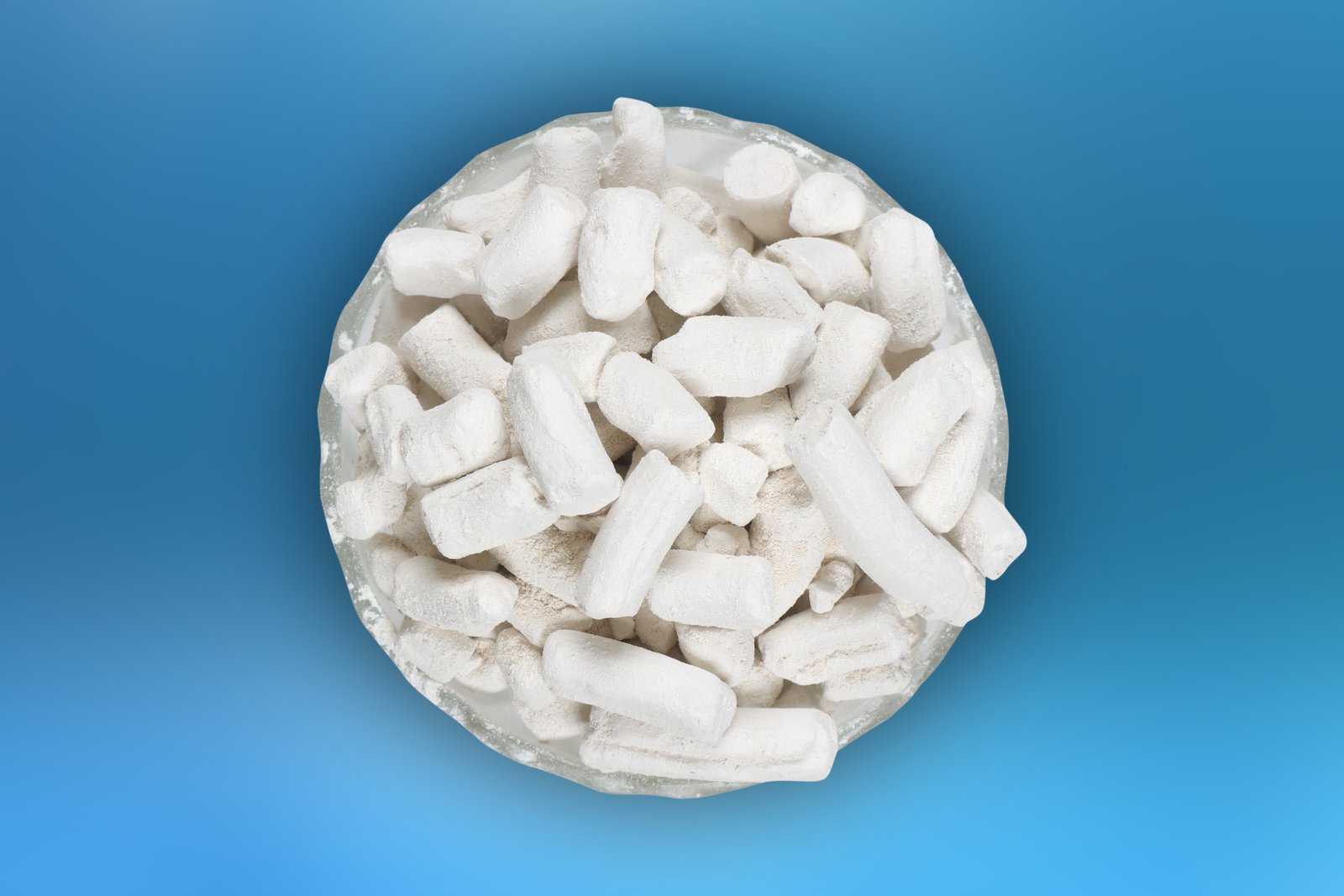

Extruded kaolin clay noodles for easy handling, reduced dust, and controlled feeding in industrial processing.

Off-white to white cylindrical noodles with good thermal stability for ceramics, refractories, tiles, construction, rubber, and foundry applications.

| Material | Kaolin Clay (China Clay) |

| Color | Off-white to white |

| Form | Extruded noodles |

| Style | Hydrous aluminosilicate clay |

| Shape | Cylindrical noodles |

| Application | Ceramics, refractories, tiles, construction, rubber, foundry |

3000 Metric Ton

Supports bulk orders with flexible packing options (25 Kg / 50 Kg / 1 MT) for domestic and export supply.

Share required quantity and destination for availability and dispatch schedule.

HDPE bags / PP bags / Jumbo bags

| K2O | TiO2 | SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | Loss on Ignition |

|---|---|---|---|---|---|---|---|

| 0.5 – 2.5% | 45 – 55% | 35 – 40% | 0.3 – 1.2% | 0.1 – 0.5% | 0.1 – 0.6% | 12 – 14% |

| Specification | Details | Specification | Details |

|---|---|---|---|

| Melting Point | 1750°C – 1785°C | Thermal Conductivity | Low |

| Specific Gravity | 2.55 – 2.65 | Dimensional Stability | Excellent at high temperatures |

| Density | 2.4 – 2.6 g/cm³ | Porosity | Low to medium |

| Strength | Moderate (improves after firing) | Water Absorption | 10% – 18% |

| Hardness | 2 – 2.5 (Mohs scale) | Foam | Nil |

| Moisture | 8 – 15% |

| Water Absorption | 35 – 55% |

| Water of Plasticity | 30 – 38% |

| Oil Absorption | 30 – 45 g / 100 g |

| Content | Data |

|---|---|

| Grain Size (D50) | 1 – 5 µm |

| Particle Size Distribution | Fine, narrow |

| Residue on 325 Mesh | 0.5 – 3.0% |

| Wet Screen Residue | < 2% |

| Surface Area (BET) | 10 – 20 m²/g |

| Content | Data |

|---|---|

| Drying contraction | 2 – 4% |

| Firing contraction | 1 – 3% |

| Total contraction | 3 – 7% |

| Contraction (overall) | Low compared to ball clay |

| Thermal Conductivity | 0.2 – 0.4 W/m·K |

| Firing Temperature | 1100 – 1300 °C |

| Thermal cycles resistance | Good |

| Cycles (mins) | 30–90 min (typical firing soak) |

| Content | pH (aqueous slurry) | Fluorine (F) | MgO | Water-soluble salts |

|---|---|---|---|---|

| Typical | 4.5 – 6.5 | <0.01% | 0.05 – 0.5% | <0.1% |

| Component | Typical Range |

|---|---|

| Kaolinite | 85–98% |

| Mica / Illite | 0–5% |

| Quartz | 1–10% |

| Feldspar / Anatase (trace) | <1% |

Quality checks and documentation to support consistent supply

We follow standard checks to ensure consistent quality and compliance.

Quality, reliability, transparency, and customer support in every shipment.

Any test reports can be shared on request at an additional cost, including third-party testing where required.

Processed grades suitable as fillers for ceramics, paper, paints, and coatings.

Common questions about Kaolin Clay Noodles

Kaolin clay noodles are used in ceramics, refractories, tiles, construction, rubber, and foundry applications. They improve handling, thermal stability, and process consistency.

Unlike powdered kaolin, noodles reduce dust, allow controlled feeding, and maintain uniformity in industrial processes.

Yes, these noodles have excellent thermal stability, making them suitable for refractory and ceramic applications.

Store in a dry, ventilated area away from moisture to preserve quality and prevent clumping.

Yes, their extruded form minimizes dust and improves safety during handling compared to powdered kaolin.

Off-white, extruded kaolin clay noodles designed for easy handling, reduced dust, and controlled feeding in industrial processes. Ideal for ceramics, refractories, tiles, construction, rubber, and foundry applications.

Kaolin clay noodles are extruded cylindrical clay pieces with an off-white to white color, engineered for industrial use where handling, consistency, and thermal stability are critical. Unlike powdered kaolin, these noodles reduce dust, improve safety, and ensure precise, controlled feeding into production processes.

They are commonly used in ceramics, refractories, tiles, construction materials, rubber, and foundry applications, providing both performance and convenience.

| Parameter | Value |

|---|---|

| Form | Extruded Noodles |

| Color | Off-white to White |

| Thermal Stability | High |

| Dust Generation | Low |

| Typical Applications | Ceramics, Refractories, Tiles, Construction, Rubber, Foundry |

Raw Kaolin | Kaolin Powder | Kaolin Noodles

A: Kaolin clay noodles are used in ceramics, refractories, tiles, construction, rubber, and foundry applications. They improve handling, thermal stability, and process consistency.

A: Unlike powdered kaolin, noodles reduce dust, allow controlled feeding, and maintain uniformity in industrial processes.

A: Yes, these noodles have excellent thermal stability, making them suitable for refractory and ceramic applications.

A: Store in a dry, ventilated area away from moisture to preserve quality and prevent clumping.

A: Yes, their extruded form minimizes dust and improves safety during handling compared to powdered kaolin.